We are the UK’s leading producer of ancient grain wheat products.

From our family farm in the stunning North East and North Yorkshire countryside, we are proud to supply 100% British ancient grains. Our award-winning spelt flour is loved by home bakers, independent bakeries and food producers alike.

What are

Ancient Grains?

Ancient grains are making a long-overdue comeback.

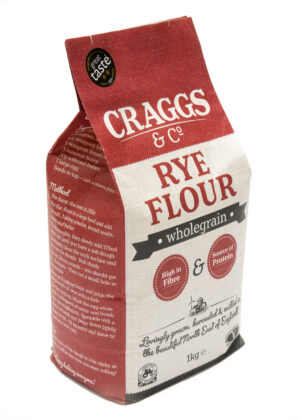

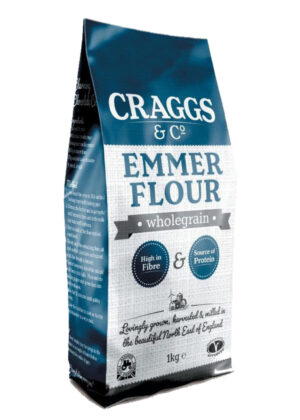

Spelt, rye, emmer and einkorn belong to a group of unrefined wheat varieties that have not been genetically modified through centuries of selective cultivation. Their origin dates back millennia, which means their high nutritional value remains unchanged.

This is compared to heavily modified modern wheat varieties which tend to give higher yields, but at the cost of higher gluten and lower fibre content.

Our Collection

The only way to find out why our ancient grain flour is causing such a stir in the baking world is to try it for yourself! Take a look at our fully traceable product range that can be purchased in either 1kg, 16kg & 20kg bags to suit your needs!

Why is our wheat special?

There are many, many reasons why our ancient grains are so special! At Craggs & Co, we are extremely proud to provide 100% British ancient grains.

It’s rare to find types of flours like ours that are exclusively grown, harvested, milled and stored locally in the UK. Every single step of our harvesting process can be traced, and each grain of wheat that goes into our products has been lovingly produced in Great Britain.

What People Say

Don’t just take our word for it! Read what our happy customers say about our flour:

Fab Bread!

“It made some fab bread and the wholegrain flour is also fine enough to make cakes with too.”

Joanne Spink

So Versatile

Steph Clubb

Perfect!

“Perfect for baking delicious bread, I have also baked yummy chocolate biscuits. Would absolutely recommend.”

Sammie

Great Flavour

“This flour is fantastic, both the white and wholemeal. These flours add a great flavour to my bakes as well as a great texture.”

Sandra

Health Benefits

What is spelt? Is it good for you?

Spelt flour is not just famous for its high-quality taste, but is recognised for its unique health properties. Ancient grains have a higher nutritional value and offer a range of dietary benefits. They can help improve gut health, migraines, gluten and fibre intake, and spelt wheat flour gives a boost to your immune system too.

Recipes

Making bread with spelt flour?

Here you will find the best recipes from Craggs & Co with tips and tricks for great quality bakes. Get inspired with our flour to bake cakes, cookies, breads, Yorkshire puds, and much more!

We know our customers love to try out new recipes! So why don’t you give these a go?

Pain d’Epices (Honey Spice Bread)

This very simple to make recipe is a breakfast staple in many a French home kitchen. Although it is called...

Honeyed Apricot Kefir Cake

Ingredients 400gm Craggs & Co Emmer Flour 250gm Soft Light Brown Sugar 330gm Plain Kefir 100gm Rapeseed...

Soft & Delicious Spelt Banana Loaf

Ingredients: 220g Craggs & Co Wholegrain Spelt Flour 30g ground almonds 2 large eggs 160g soft brown...